With the development of modern technologies and Industry 4.0 standard, the production technologies in industry have changed. Thanks to the falling price of new technologies and rising labor costs, robotics and production automation are promising for many companies. Automated production is capable of minimal work cycles, but any product change requires a complete line reconstruction. The advantage of robotization is its versatility and flexibility while maintaining short production times. The robot represents a human being in repetitive, lengthy or dangerous work. This minimizes the risk of accidents at work and reduces scrap. Employees are freed for more skilled and safer jobs. Overall, this leads to an increase in the productivity of production with the current number of employees.

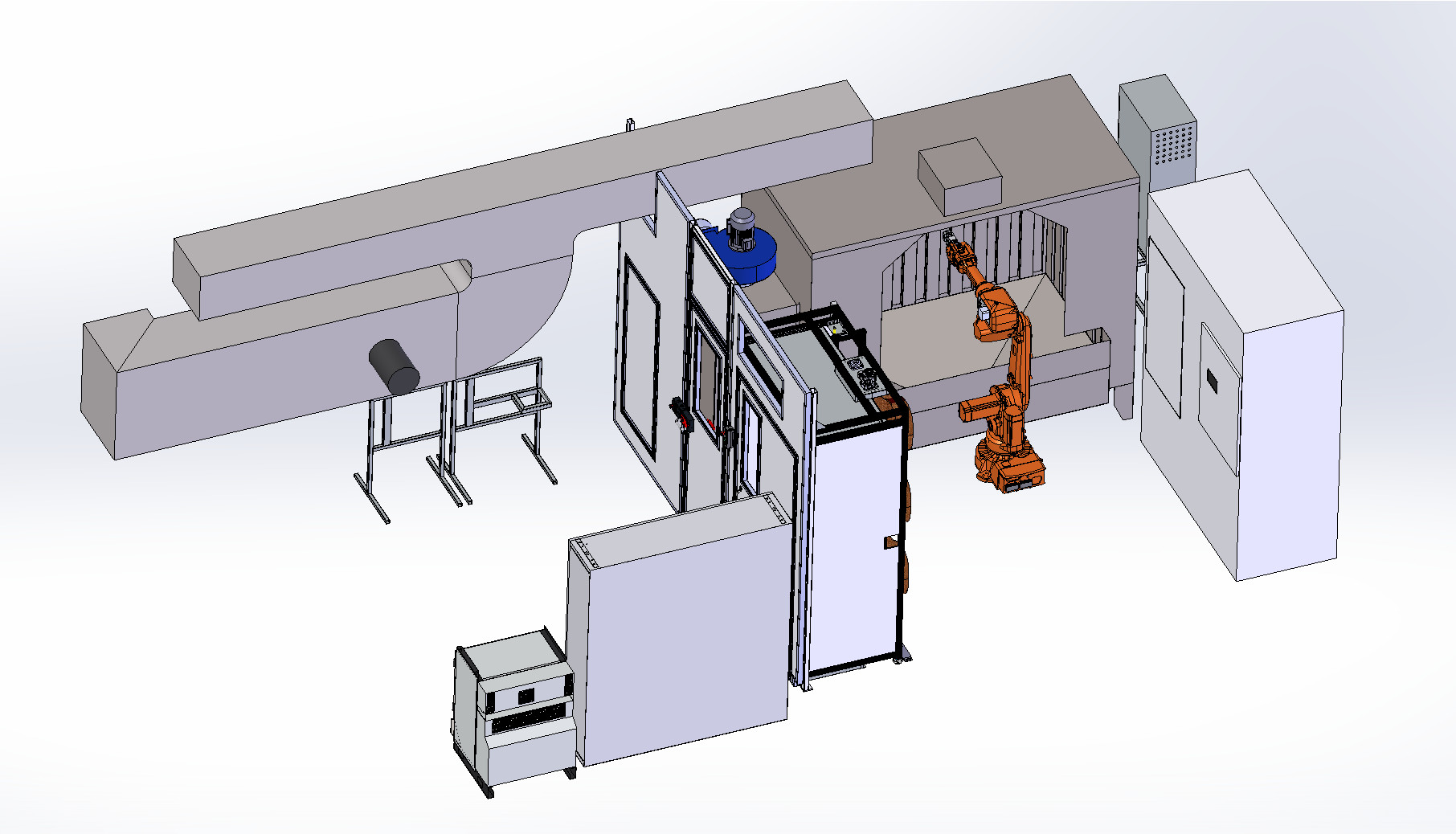

Aeroterm, a.s. responds to these trends by extending its portfolio to design and manufacture customized robotized cells. We conducted a thorough search of the industrial robots market and chose suppliers for individual areas of robotics. We cooperate with world leaders whose products can be used for applications where competing products could be used only to a limited extent or not at all. Our key robot suppliers include:

ABB Robotics

The world’s leading supplier of industrial robots. Many types with different reach and load capacity. Highly configurable control system.

Universal Robots

Collaborative robots with simple programming that have found their way to many manufacturing companies for their versatility.

Omron

High precision SCARA robots, AGV (automatically guided robot vehicles for in-house transport).

We are able to deliver robotized manufacturing cells to all areas of industry. The most common industries include:

- automotive

- food industry

- brewing

- woodworking

- furniture

- printing

- machining

The robot can perform technological or handling operations. Depending on the application, the workplace can be equipped with additional features such as remote secure access for diagnostics and program modifications, interconnection with the company network or a camera system for workplace monitoring.